Fiberglass vs. Vinyl Pool vs. Concrete Pool

Complete Guide: Fiberglass Pools vs. Concrete Pools (Gunite) vs. Vinyl Liner Pools

When choosing an inground pool, you have three choices: vinyl liner, fiberglass, and concrete (also referred to as shotcrete or gunite). There are pros and cons for each type of inground swimming pool. We identify the fiberglass vs. vinyl pool and the fiberglass vs. concrete pool in our overview below.

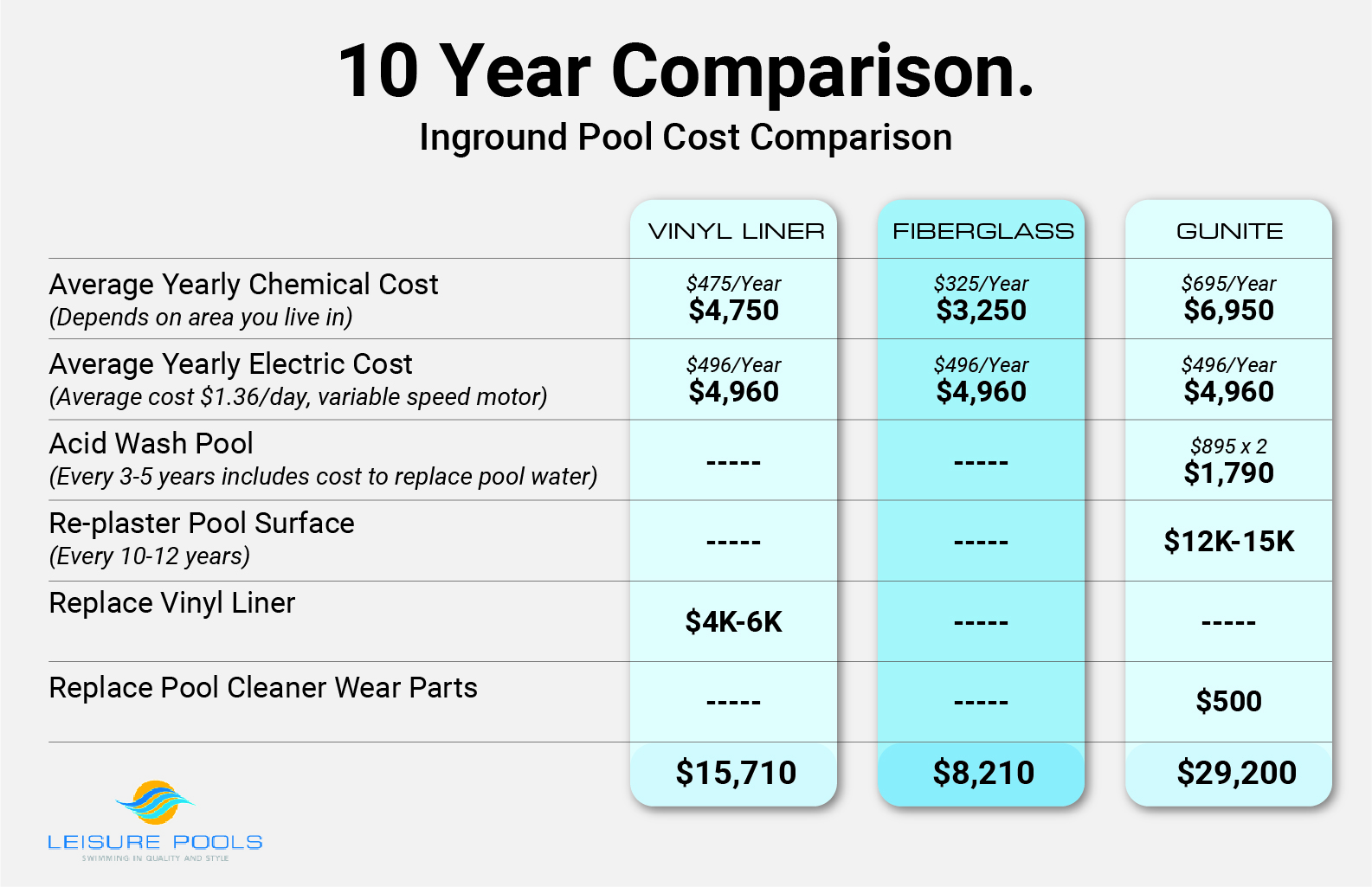

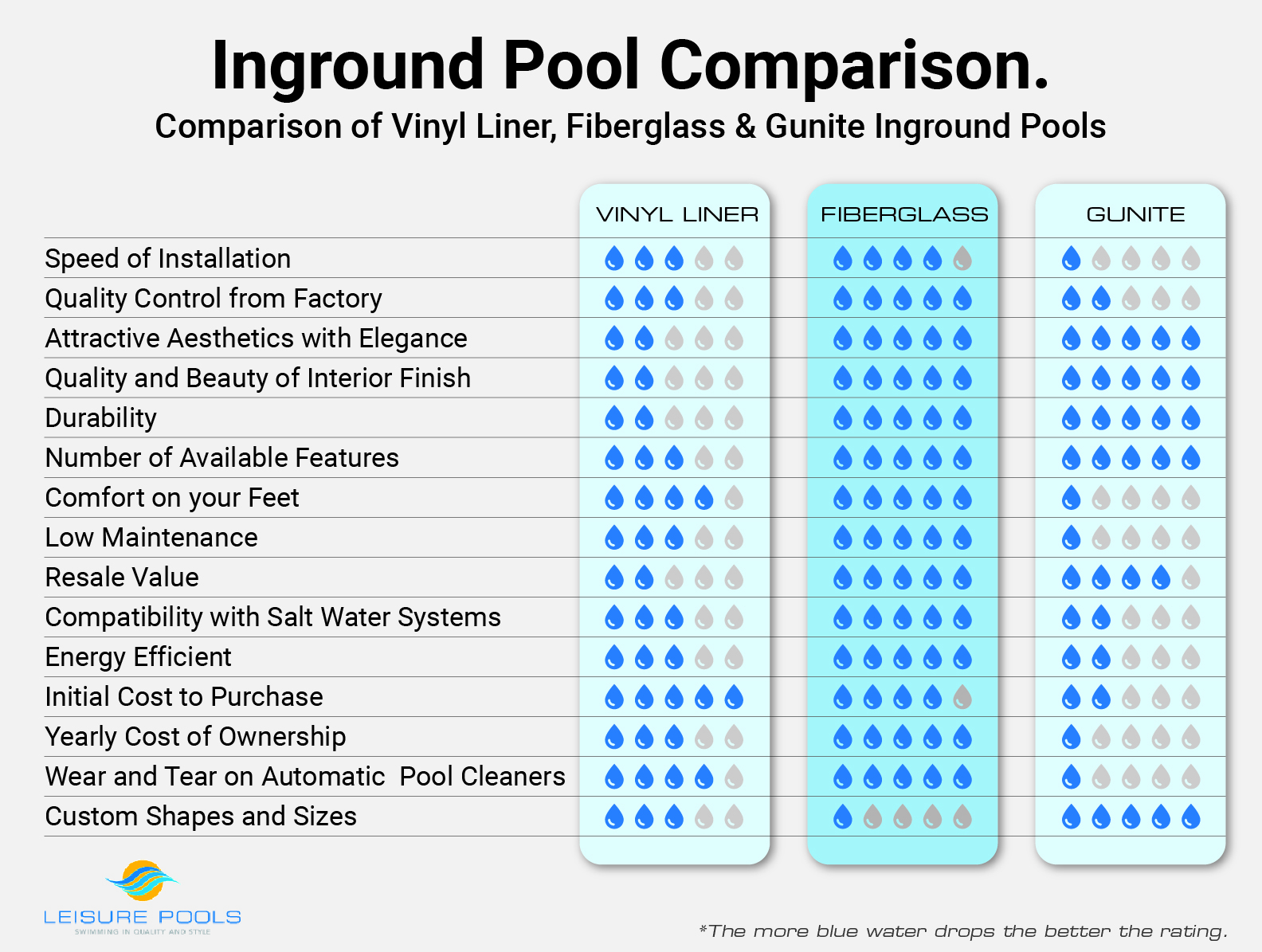

As you can see from the chart below, fiberglass pools are the most favorable choice, coming out on top in most categories. Keep reading to see why.

What You Will Learn In This Guide:

Advantages of Inground Fiberglass Pools

Disadvantages of Fiberglass Inground Pools

Advantages of Vinyl Liner Pools

Disadvantages of Vinyl Liner Pools

Advantages of Concrete (Gunite) Pools

Disadvantages of Concrete (Gunite) Pools

Fiberglass Pools vs Vinyl Liner Pools Comparison

Fiberglass Pools vs Concrete (Gunite) Pools Comparison

Advantages of Vinyl Liner Pools

Initial Lower Cost

Traditionally, vinyl liner pools are the lowest cost of entry into owning an inground pool. They provide an economical budget solution to families looking to enter the inground pool market.

Ability to Customize

Even though you are limited to shapes and sizes, there is more ability for customization than with a fiberglass pool. Most vinyl liner pools are rectangular; however, they have developed a broader range of shapes and sizes than fiberglass can currently offer.

Disadvantages of Vinyl Liner Pools

Vinyl Liner Replacement

The most significant disadvantage of owning a vinyl liner pool is the frequency in which you need to replace your liner. Under normal circumstances, the average liner replacement is approximately 8-10 years, depending on how the pool is maintained and the area of the country you live in.

If water chemistry is not maintained at an ideal level, the liner will become hard, brittle, and wrinkles will form. When the chlorine level is high, the liner will become bleached, resulting in a loss of color.

If you live in the Sun Belt and the liner is in direct sunlight all day, the corners above the waterline can dry out and also fade out from the intense sun.

Warranty on Vinyl Liner and Structure

Most vinyl liner pools have very ambiguous warranty clauses. Some manufacturers state that the liner has a 20-year limited warranty, a three-year full warranty, and a seventeen-year prorated warranty. You have to read the fine print. There is hidden legal ease protecting the manufacturer, which is not in your favor. There is also a limited warranty on the pool structure, which includes the sidewalls and floor, which is usually not extensive.

Still, deciding on fiberglass vs. vinyl pool? Let us proceed so you can learn more about the fiberglass vs. concrete pool.

Advantages of Concrete Pools (Gunite Pools)

Complete Customization of Size and Shape

The ability to customize any size and shape inground pool is the number one advantage of concrete pools. Because the pool is formed from steel and then the concrete (gunite or shotcrete) is blown in, your ability to customize is endless. Of course, this comes with a significant price tag, but someone who is looking for complete customization may not be concerned with cost. If you are looking for a unique shape, or multiple bodies of water that flow into one another, or maybe a lazy river pool, then concrete can provide a solution for you.

Durability

Similar to fiberglass, concrete pools are also very durable. You do not have to worry about tearing a liner or causing a leak when Fido, your loving pet, decides to scrape the pool steps. Yes, the fiberglass vs. concrete pool question regarding pets is that both are animal friendly. You can take Fido for a swim and not worry about damaging the pool.

If you live in a rural area where there is an abundance of bears, a vinyl liner pool is not a great choice. Bears and their cubs have been found on occasion, taking a dip. Fiberglass or concrete is the recommended choice for these areas.

Although concrete is sturdy and durable, it will not last as long as the gel coat on fiberglass before it needs reconditioning.

Disadvantages of Concrete Pools (Gunite Pools)

Most Expensive Pool to Own

After viewing the fiberglass vs. concrete pool 10-year comparison chart, you will see that concrete pools are by far the most expensive pools to build and own. They cost significantly more to construct and maintain. Concrete pools require the most maintenance vs. vinyl liner or fiberglass pools. They are prone to staining on the bottom and sides if you do not maintain and balance the water chemistry. The cost of acid washing and resurfacing are exceptionally high priced, thus costing significantly more over time.

High Maintenance Costs

Whether you hire an outside pool professional or do the maintenance yourself, concrete pools require the most maintenance of all inground pools. Right from the time, you take possession, and after the pool is installed, the pool builder will go over the strict maintenance plan required as the interior surface cures.

It doesn’t stop there. Once the project is completed, a regular maintenance plan must be put in place to maintain the integrity of the pool surface. Concrete is very porous, and if not managed properly, it will stain and deteriorate rapidly.

Draining the pool and acid washing is the only way to remove these stains and over time, will become permanent stains. The only way to remove them is to re-plaster the pool’s surface. Acid washing can also wear down and damage the surface as well, causing you to re-plaster sooner or more often

Use More Chemicals

Water chemistry is an integral component of the ongoing maintenance of concrete pools. Using chemicals and balancing them properly is vital; otherwise, damaging the interior pool surface, resulting in a costly repair is inevitable.

Due to the porosity of concrete, it requires more chemicals for maintenance than either vinyl liner or fiberglass pools. Concrete naturally increases alkalinity (pH), which requires continually adding acid to keep a stable pH balance.

Abrasive Interior Surface

Have you ever been swimming in a concrete pool and have found it to be very rough on your feet? Concrete pools have abrasive bottom and sides which are not as smooth as fiberglass or vinyl liner pools. When it comes to comfort, fiberglass vs. concrete pool, nothing is smoother than a fiberglass pool with vinyl coming in second.

The coarse surface is also tough on automatic and robotic pool cleaners, wearing out pool cleaner parts much sooner.

Longest Installation Time

Compared to fiberglass, installing a concrete pool could be as much as three times longer. This process is very wearing and can exhaust a family who is excited and waiting to swim in their new pool.

Let’s Sum It Up!

Fiberglass vs. Vinyl Pool

Fiberglass Pool

-

-

- Durable

- Low Cost of Ownership

- Installation is Quick

- Compatible with Salt Systems

- Low Maintenance

- Low Lifetime Cost of Ownership

- Long Warranty

-

Vinyl Pool

-

-

- Initial Low Cost to Purchase

- Some Customization Available

- Liner Replacement Needed Approximately every 8 to 10 years

- Ongoing Pool Chemical Balance is Vital

- Maintenance is Essential

- Ambiguous Warranty Clauses

-

Fiberglass vs. Concrete Pool

Concrete Pool

-

-

- Durable

- Complete Customization Available

- Abrasive Surface

- Installation Can take 8 Weeks to 4 or 5 Months

- Ongoing Pool Chemical Balance is Vital

- High Maintenance

- Re-Plastering Needed Over Time

- Extremely High Cost of Ownership

-

Do you still have a question regarding fiberglass vs. concrete pool or fiberglass vs. vinyl pool? If so, get in touch with Leisure Pools today. One of our professional pool representatives will be happy to speak with you and address any of your questions or concerns.